Modular system composed of a metal substructure with self-standing uprights covered with prefabricated panels including: high performance acoustic gaskets, fine-tune adjustable feet, rounded ceiling and flooring profile and FDA approved sealing gaskets (X-ray protection available for partitions, doors and windows).

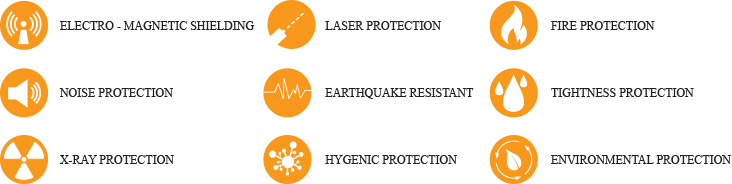

The System is all-round customizable and includes: manual automatic doors, hermetic ceiling lights, static dissipative floorings, laminar air flows... And many more accessories such like: control panels, digital clocks, PACS units, Pass-through windows cabinets, x-ray viewers and cabinets.

Substructure composition

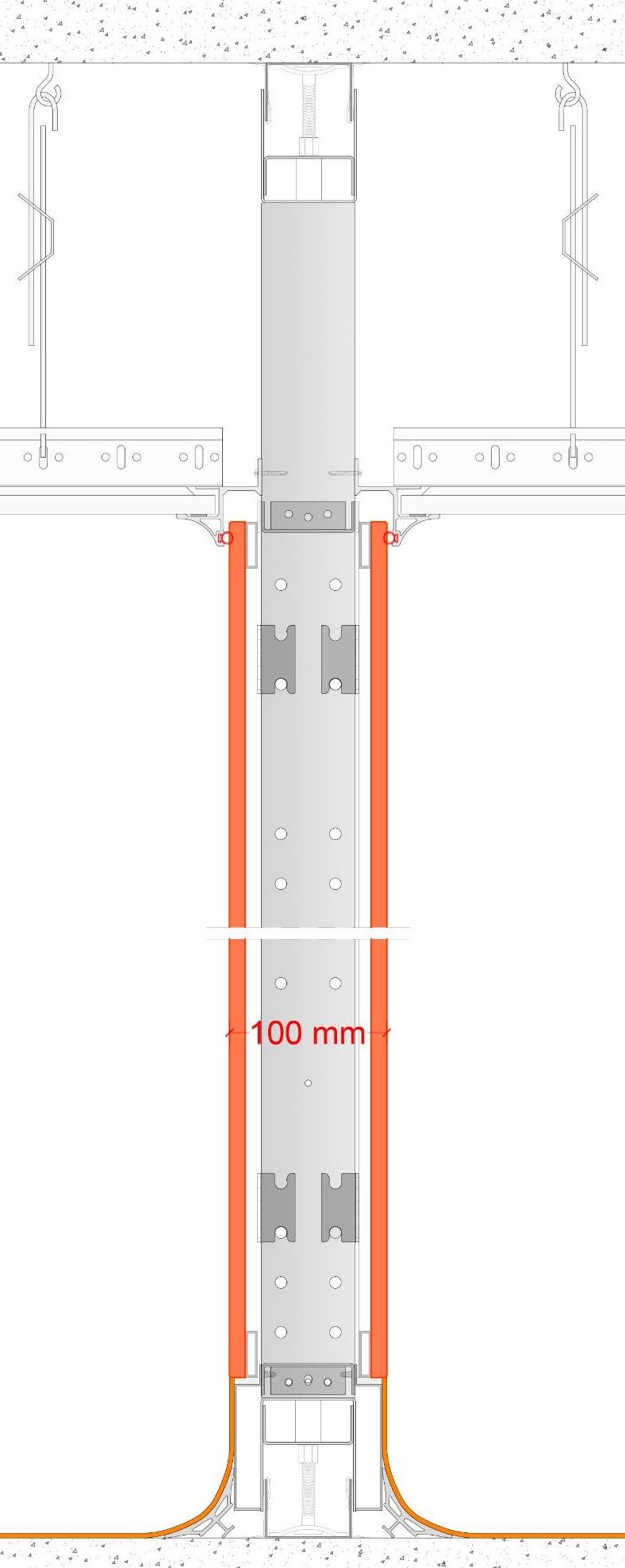

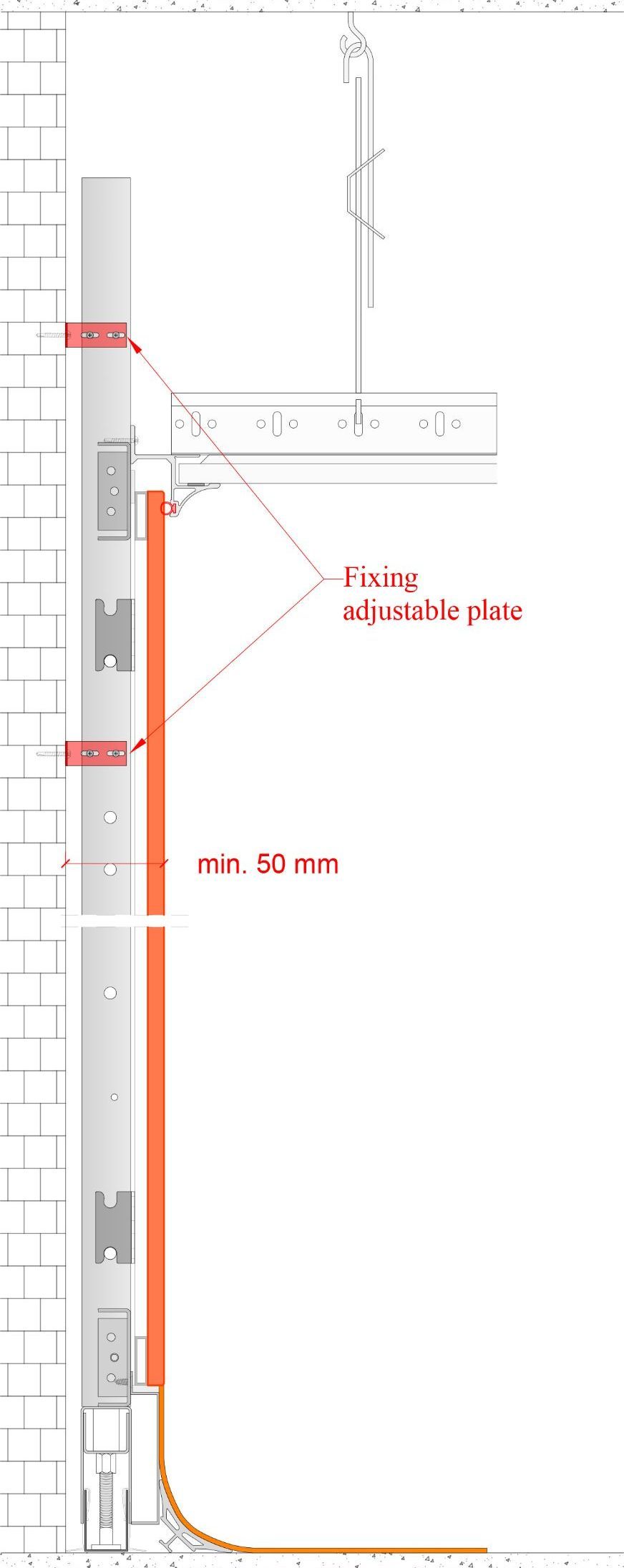

- Uprights made of galvanized steel, dim. 60x30mm, thickness 2mm with adjustable feet;

- Horizontal spacer or bars made of galvanized steel;

- Floor and ceiling rail made of galvanized steel 1mm sheet;

- Vertical and horizontal structures provided with buttonholes to allow the passage of cables and pipelines;

- Special neoprene closed cell soft gaskets on all structural elements to seal firmly the frame with the covering panels;

- A PVC perimeter profile allows the flush connection between the wall and the floor - radius 45mm.

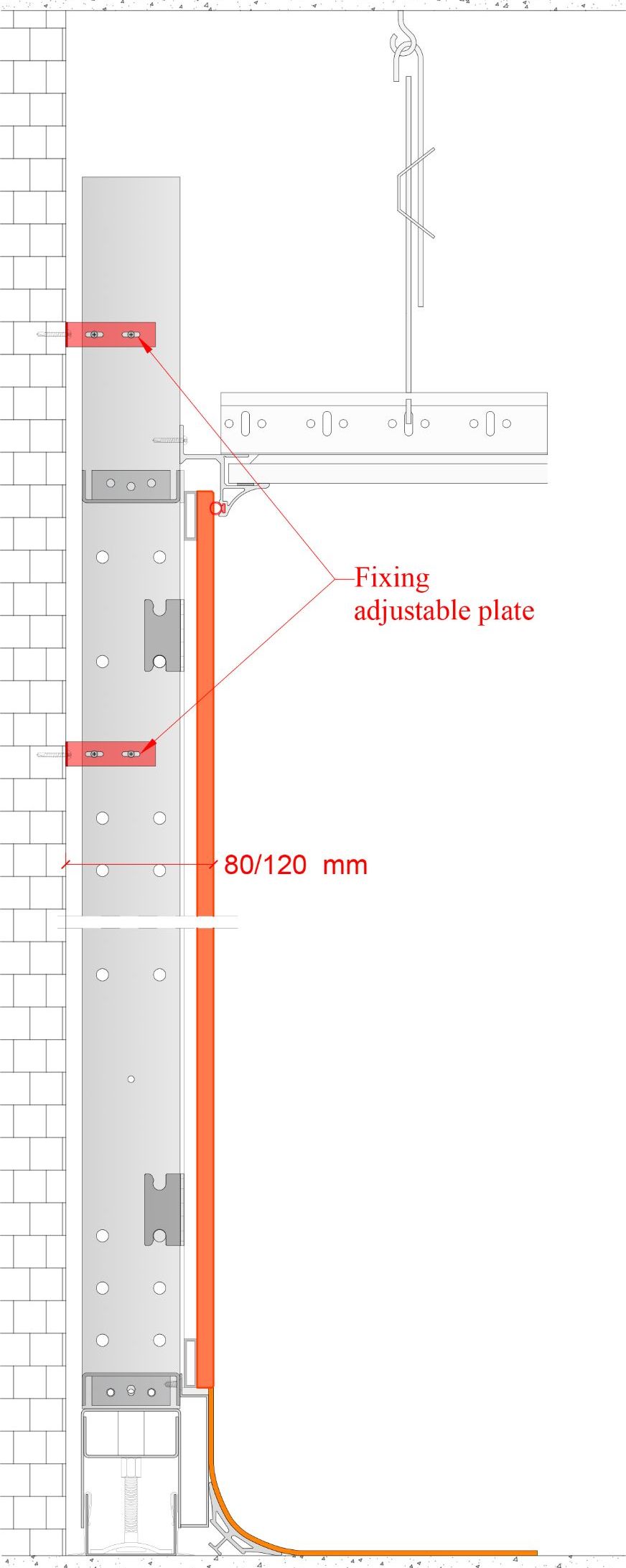

Self-standing upright (up to 550cm)

The uprights are made of high thickness galvanized steel (dim. 60x30x2 mm). Such a high thickness guarantees a particular strength. They are able to withstand any static and dynamic stress from pensiles, panels and sliding doors. The core of the Salus system is the sub-structure that lie behind the face panels. This kind of structure is specifically designed to satisfy the highest standards of cleanliness for sterilized areas. The framework is able to get inside all the required utilities. The sub-structure is entirely made of galvanized steel and it ensures both components dimensional stability and maximum resistance to fire. All components are class 0 fireproof.

Covering panels come in many different materials

Some examples:

Just ONE product, but many DIFFERENT solutions

A

OPEN SPACE SOLUTION

Single structure solution to be used in open space areas when integrated equipments have limited thickness (less than 80 mm).

B

CLADDING SOLUTION

Single panel solutions to be used as a cladding of existing walls. This cladding solution, floor to ceiling fixed and completely independent from the existing walls, allows the integration of any kind of equipment even with very important thicknesses of more than 80 mm.

C

CLADDING SOLUTION

Cladding solution with minimal structure fixed to existing wall. This solution can be used when there is no integration in the wall and you have to optimize as much as possible the internal space of the room.

D

CLADDING SOLUTION

Cladding solution with standard section fixed to existing wall. This solution can be used when the integrated equipment have limited thickness (less than 80 mm) and you have to increase the internal space of the room.